Introduction

More and more Hospitals see in 3D printing a way to gain autonomy when manufacturing by themselves some of the Customized Medical Devices they need. 3D printing enables the translation of virtual three-dimensional reconstructions into tangible models, thus facilitating the work of the specialist.

Already in 2015, the Emergency Care Research Institute (ECRI) ranked 3D printing second among the 10 technologies with the greatest healthcare impact, and its boom is growing every year thanks to advances that make it increasingly accessible to hospital centers.

"3D printing at "POINT-OF-CARE (POC)".

Customized Medical Devices manufactured by the hospital (“in house”) using 3D printing, for its own use, are known as “3D printig at POINT-OF-CARE (POC)” products, which in colloquial language could be called “do it yourself”.

Although Spain is not a leading country in its use, 3D printing is already applied in some healthcare fields, the best known being:

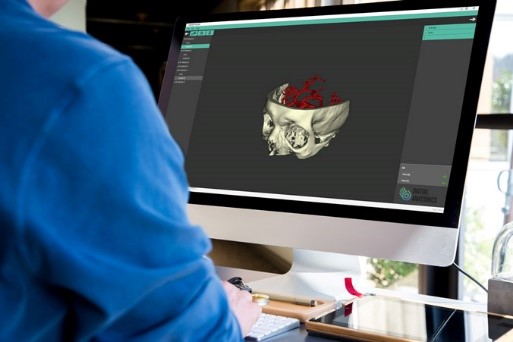

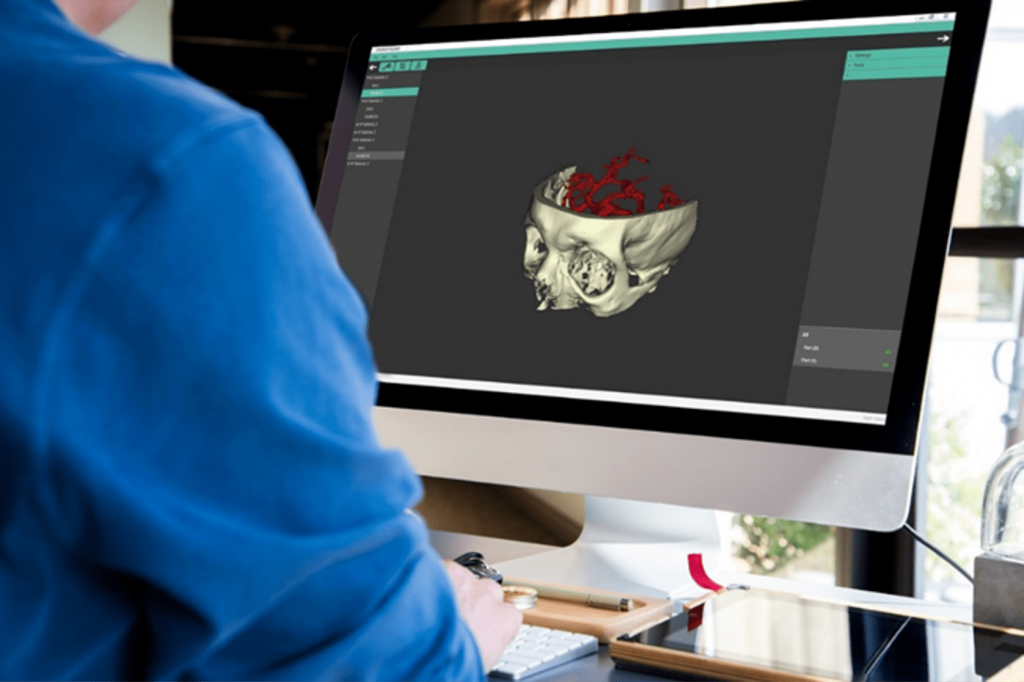

–Anatomical biomodels, which are reconstructions (replicas) of patient anatomies.

Examples of biomodels manufactured by Digital Anatomics: 1) Skull base aneurysms, 2) Expansive lesion of cavernous sinuses, 3) Internal auditory canal meningioma, 4) Dorsal meningioma after decompressive surgery.

These biomodels are mainly used to:

- Complement diagnosis, planning, simulation of surgeries and preforming of surgical meshes.

- Communication and training between professionals

- The approach to the patient, helping him to obtain a better understanding of his ailment and the treatment to be applied.

Examples of surgical planning, communication between professionals and approaching the patient to the disease.

3D printing in "In House" Customized Medical Devices

- Surgical guides that allow the performance of surgeries with greater precision, more safety for the patient and shorter intervention time (up to 30% less than a traditional one). In turn, it allows less experienced surgeons to start complex surgeries more easily, thus performing a greater number of operations.

The benefits of custom-made POC medical devices are unquestionable and are responsible for the growing interest in “do it yourself“:

- The direct contact of the surgeon with the technician who makes the 3D reconstruction, being able to visualize “in real time” his progress and guide him according to the needs of each specific case.

- The immediacy from the request of the 3D product to its use, which is a key factor in unplanned surgeries where there is no waiting time.

European regulations

Until relatively recently, the regulation on “in house” medical devices was diffuse, as they were not mentioned in the old directive 93/42/EEC . However, the new European regulation on medical devices (Regulation (EU) 2017/745, in its Article 5-paragraph 5), does include the requirements that hospitals must comply with, in case they want to jump on the POC bandwagon and become manufacturers of these custom-made medical devices.

In summary, the hospital would have to comply with the following requirements:

Compliance with these regulations requires hospitals to invest heavily in human resources and equipment to design, manufacture, control and monitor the medical device, processes in which they may not be specialized.

ARTEMIS 3D: Hospital 3D units from Digital Anatomics

A solution to the conflict between the need for biomodels, surgical guides, etc., and compliance with the legislation affecting POC activity is represented by Digital Anatomics’ hospital 3D Units (ARTEMIS 3D).

In each ARTEMIS 3D, Digital Anatomics staff and equipment are installed in the hospital and act as a service of the hospital.

This generates that direct contact and immediacy so valued by medical professionals, while they can count on all our know-how as experts in 3D technology that we update in real time.

These units operate under Digital Anatomics’ Custom Medical Device Manufacturer’s License and ISO13485 and ISO 14001 Management System, which is now extended to the location provided by the hospital. As a result, the hospital does not need to divert any resources or effort away from its healthcare business.

Another element to highlight is that the ARTEMIS 3D model represents a significant cost saving for the hospital, if labor costs are taken into account, as well as equipment acquisition and maintenance costs.

At Digital Anatomics we have our own software, which gives us great autonomy and flexibility in terms of both costs and execution times.

ARTEMIS 3D is Digital Anatomics’ proposal to achieve the perfect balance between “do it yourself” and respect for the Medical Device Regulations, optimizing Hospital operations and specialist and patient satisfaction.