Introduction

The constant development of new technologies is one of the causes of the growth and evolution of the society in which we live. 3D printing is an example of innovation and progress that is emerging in different professional fields. However, medical 3D printing is one of the sectors that is growing the most, becoming a powerful tool to improve our lives today and to glimpse a promising future.

What is 3D medical printing in medicine?

The beginnings of additive manufacturing technologies date back to the 1980s. 3D printing emerged in parallel to the creation of inkjet printers, and its progressive advances facilitated the emergence of this technology in material printing.

Its function involves creating a digital model of a product, creating a prototype of the model in question layer by layer, using the appropriate material for each case. In this way, it moves from the digital to the physical plane by giving volume to that three-dimensional image. 3D printing in medicine represents a paradigm shift in the healthcare sector, which has been booming since the last decade.

The beginnings of additive manufacturing technologies date back to the 1980s. 3D printing emerged in parallel to the creation of inkjet printers, and its progressive advances facilitated the emergence of this technology in material printing.

Its function involves creating a digital model of a product, creating a prototype of the model in question layer by layer, using the appropriate material for each case. In this way, it moves from the digital to the physical plane by giving volume to that three-dimensional image. 3D printing in medicine represents a paradigm shift in the healthcare sector, which has been booming since the last decade.

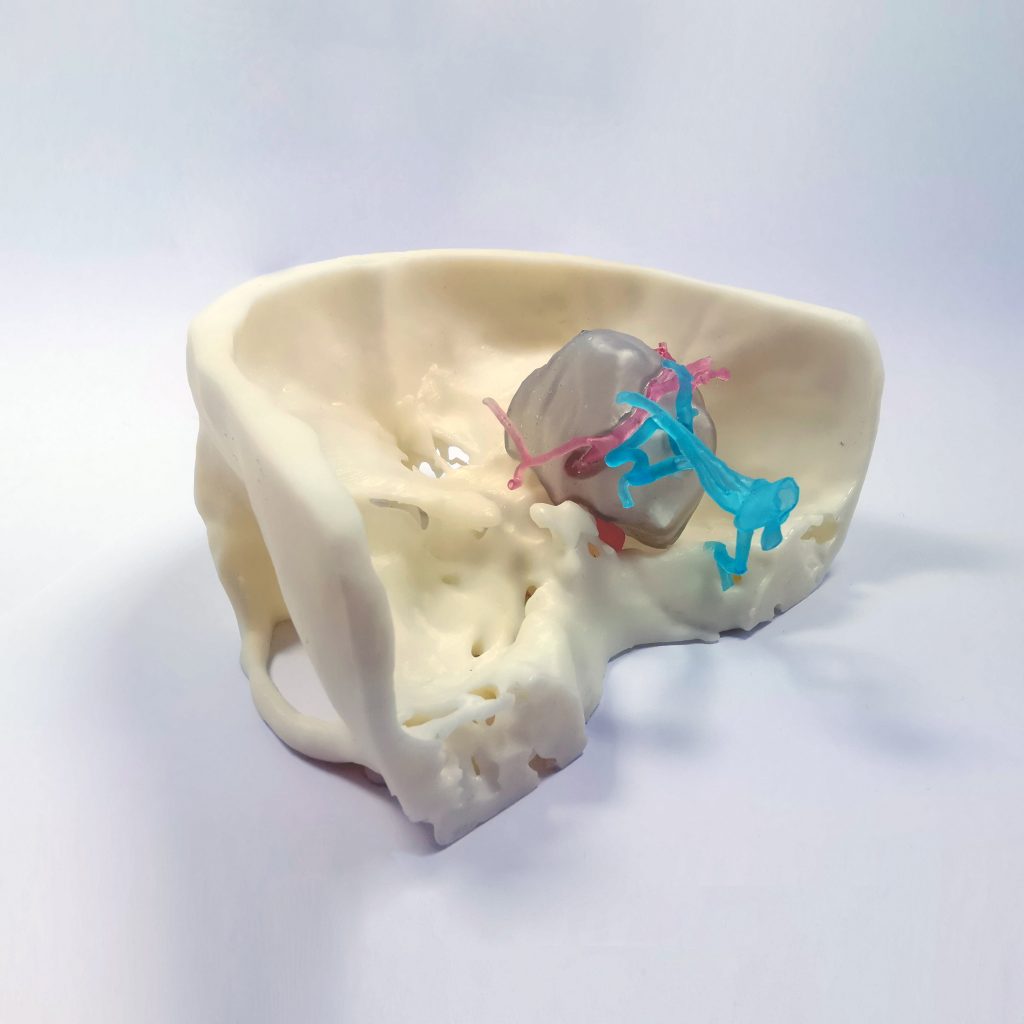

These will be studied to preserve, as far as possible, the original anatomy of the structures prior to their reproduction. In this way, an exact replica of the anatomy of interest in each case is printed. The objective of this scientific innovation is mainly reflected in the ability to manufacture personalized and functional parts, following a more automated process. Therefore, it helps the professional to find a solution or alternative for the treatment or pathology of each patient in a simpler way, practicing on the printed organ before the intervention. In addition, it favors a two-way and closer communication between the doctor and the patient, where the latter can know details of his condition and treatment.

The use of 3D printers is not only aimed at the creation of new products, but also at the customization of existing models, i.e. products made to measure according to the case to be treated, thus becoming its greatest advantage.

The consequence and advantage of this technology is reflected in the result, since it leads to a more effective treatment, a shorter duration of surgery and, therefore, a faster recovery of the patient.

In order to achieve these objectives, the use of 3D printers is necessary as the only indispensable resource. An industry has been created around them and more and more companies are using and relying on this technology, the demand for which is growing by leaps and bounds. In addition, they avoid the need for stocks, since the requested tools or parts can be obtained on the same day. If a problem arises with any part of a part or a way to improve it is discovered, it is only necessary to update the CAD file and print the updated part.

On the other hand, and as a consequence of the emergence of medical 3D printing, bioprinting arises with the aim of achieving exact replication of soft tissue and its material. In this way, these printed organs can be transplanted into individuals.

These tissues and organs are made from the patient’s stem cells, so that once again the final product is completely personalized, adapted to the needs of each patient. It should be noted that the risk of incompatibilities has yet to be assessed.

How is 3D printing used in the medical industry?

In recent years, this scientific innovation is spreading rapidly, and there are several uses in modern medicine that employ 3D printing and the potential applications that may arise from this technology. These advances favor the possibility of offering tools that can be applied and integrated into any medical service that wishes to do so, thus opening up a new labor market.

Given its versatility and its acceptance by users as an innovative technology, 3D printing in medicine has enabled a reduction in costs, offering a wider range of possibilities for use, from the customization of prostheses adapted to the needs of each patient as well as medical instruments to the printing of anatomical models for training in universities or in different health centers. In any case, it allows to simulate and train the surgeon by facilitating surgical planning.

Currently, several technologies can be distinguished within 3D printing in medicine, from surgical guides, anatomical biomodels, dental teaching, pharmaceutical research to software applications.

Any of the uses that can be given to 3D printing in the health sector has the final objective of bringing benefits in terms of improved results, derived from the minimization of risks and reduction of time.

In addition, better communication is established between the doctor and the patient, since the latter will more easily understand the problem that concerns him or her, as well as trusting and feeling more confident, since the treatments are less invasive and rehabilitation times are shorter.

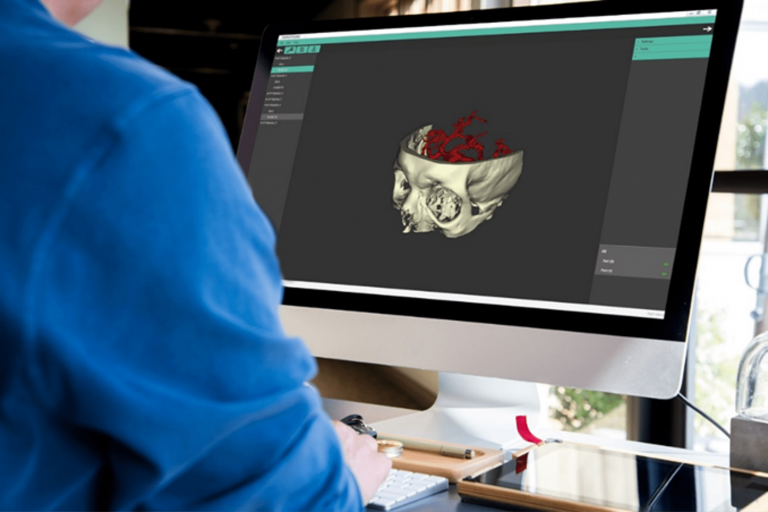

We could differentiate three types of software within the scope of the customized product.

-Software for image segmentation.

-Software for editing three-dimensional meshes.

-Software for 3D printing lamination.

The segmentation software is used to transform the two-dimensional images of radiological or resonance tests into three-dimensional volumes. These types of programs have algorithms that facilitate the selection of anatomical regions or pathologies, by means of contrast or image recognition techniques.

Some examples of these programs are open source platforms such as 3D Slicer or Invensalius. At Digital Anatomics, we start from previous developments in the form of open source libraries together with our own algorithms to make reconstructions more automatic. All these proprietary or third party algorithms must be subjected to verification tests in order to comply with the new Health Regulation.

The mesh editing task is performed with algorithms that allow exhaustive analysis of possible errors such as holes, shells, inverted normals or their subsequent repair.

Also useful are algorithms for remeshing, smoothing, measuring and geometry generation, for example, for the design of customized surgical guides. At Digital Anatomics, we follow the strategy of combining the power of open source graphics editing engines with our own developments, in order to improve accuracy, automate and speed up designs as much as possible.

Finally, the lamination programs are usually the 3D printer manufacturers’ own. Their function is to translate the three-dimensional models into the language of layers or sheets of these 3D printers, configuring the necessary parameters depending on the type of machine or material. When manufacturing the part, a series of precautions included in the company’s quality management system must be taken to avoid errors and ensure non-contamination, in the case of the use of biocompatible materials.

Currently, the general trend and Digital Anatomics’ commitment is automation. Therefore, we are working on different lines of development that allow the software user to be the doctor or dentist himself, creating simpler and more specific tools that manage to execute a guided design thanks to the combination of different techniques with the use of artificial intelligence. This will lead to a faster and more affordable adoption of these new technologies.

Can medical 3D printing help to reduce costs?

When it comes to new technologies, they are usually associated with high costs for companies. However, this is changing due to different factors that are facilitating their popularization.

In the case of 3D printing in medicine, professionals need customized tools, since operations are prepared and adapted to the case of each patient. Therefore, if the hospital or doctor had their own 3D printers, it would increase versatility, quality, immediacy, flexibility and, as a consequence, optimization in the design and manufacture of their parts. This would reduce production and manufacturing costs thanks to the additive manufacturing process. In this way, scale models are built, at a lower cost, allowing to see and test the product before manufacturing it as such.

In addition, it opens the way to the free production of customized products and medical equipment, which provide freedom of action for the surgeon during the intervention. This generates high value for medical staff and patients, since operating room times are reduced as well as the risks involved in interventions. All this translates into greater savings in the long term.

Thanks to them, companies can save costs in 3D printing, streamlining the manufacturing process and optimizing the production chain.

Looking ahead, there is room for improvement in the sector as it is a field yet to be explored, despite its rapid expansion.

What are the benefits of using 3D printing in medicine?

As discussed above, there are multiple benefits of establishing a relationship between healthcare facilities and 3D printing.

3D design in medicine has become a very useful tool that allows better communication between doctor and patient, greater understanding between teacher and students in the teaching/training of case studies, as well as the study of more complex cases that involve greater risk and precision in the intervention. In this way, clear benefits arise for both parties in the field of surgery.

On the one hand, the patient will have a better understanding of his problem and the intervention process he or she is about to undergo. In addition, the interventions will be less invasive, speeding up the recovery process and reducing the risks involved in such interventions and the exposure time to X-rays.

On the other hand, the hospital has the same advantages as the patient and, in addition, the reduction in operating room time translates into a reduction in costs. The freeing up of operating room hours will allow a greater number of interventions to be carried out, increasing productivity. As a final advantage, it contributes to the training of residents.

In the event of any failure or modification in the design of a part, there is greater flexibility and a faster solution to mishaps or errors in the design of the same.

What is the future of 3d printing in PoC?

3D printing technology in medicine is achieving very positive results in a short time. Despite the short life of this technology, thanks to its evolution it can already be applied in different fields of study.

One of them is the manufacturing of tailor-made medical devices at the Point of Care (PoC), meaning the place where the engineering functions will be developed in terms of prototype/model design and manufacturing.

The point of care would be located in hospitals and clinics where engineers provide immediate information to healthcare personnel, who make decisions regarding patient diagnosis and treatment.

Currently, 3D bioprinting is already becoming the technology with the greatest potential for producing soft tissue. Therefore, thanks to constant improvements and advances in 3D printing techniques, it will be possible to bioprint functional tissues and organs and transplant them into a human being with complete safety.

For greater effectiveness in the production of these tailor-made medical devices and biological structures, what could be better than manufacturing them in the hospital itself, minimizing errors in their design, reducing travel times, fluid communication with the surgeon and, therefore, real-time interaction, visualizing progress and guiding the engineer according to the needs of each specific case.

Another key factor lies in the immediacy of action from the request for the 3D product to its use at the pace of the hospital, including emergencies, where there is no waiting time.

All these factors promote better clinical, operational and economic results.

Artemis 3D. Digital Anatomics' PoC solution, why might it be the most competitive solution on the market today?

Hospital 3D units offer an integrated service in hospitals to facilitate the processing of anatomical images, design and 3D printing of customized devices in surgery, and increasing awareness and commitment on the part of those involved.

Digital Anatomics performs all processes with 100% proprietary technology, including software. This allows speeding up the design and manufacturing of biomodels and surgical guides.

Thanks to the customization and maintenance of the 3D printers and auxiliary equipment, the 3D printing processes carried out are proprietary and efficient.

Artemis 3D is staffed by Digital Anatomics employees.

Artemis 3D brings together all our experience, making the challenge of digitization a reality, which until now has faced many barriers:

The cost is affordable for any hospital center, as we have our own software, processes and maintenance.

It allows an agile design and manufacturing.

Implementation is almost immediate.

We extended our license as a custom-made medical device manufacturer to the integrated service, complying with the new regulations that restrict 3D printing by the hospital itself.

Hospital 3D printers and other equipment remain permanently updated and optimized.

Outsourcing is applied as a contractual service model. When applied over a period of one year, it facilitates budget planning and simplifies “purchasing” within the current regulatory framework.

BIBLIOGRAPHY:

- https://ingenieria3ddigital.es/servicio-de-impresion-3d/ventajas-y-desventajas-de-la-impresion-3d/

- http://www.3dprintingdesign.es/es/noticia/el-papel-de-la-impresion-3d-en-la-medicina-del-futuro-tras-la-pandemia

- https://www.redaccionmedica.com/secciones/ingenieria/impresion-3d-hospitales-mejoras-paciente-practica-clinica-7479

- https://impresioni3d.com/evolucion-de-la-impresion-3d/

- https://3dheals.com/3d-printing-at-point-of-care

- https://www.3dlifeprints.com/

- https://www.impresoras3d.com/impresion-3d-hospitales/

- https://www.interempresas.net/Fabricacion-aditiva/Articulos/326752-El-sector-de-la-salud-se-rinde-a-las-ventajas-de-la-impresion-3D.html (25/02/2021)

- https://www.3dnatives.com/es/la-impresion-3d-170720182/

- https://dynapro3d.com/

- ABC Empresa 11/07/2021